From our structural work for LUMC in Leiden and our long-standing relationship, we regularly advise on solutions that are both environmentally friendly and cost-saving. So too with regard to lead glass. Curious about possibilities to lead glass sustainable deployment?

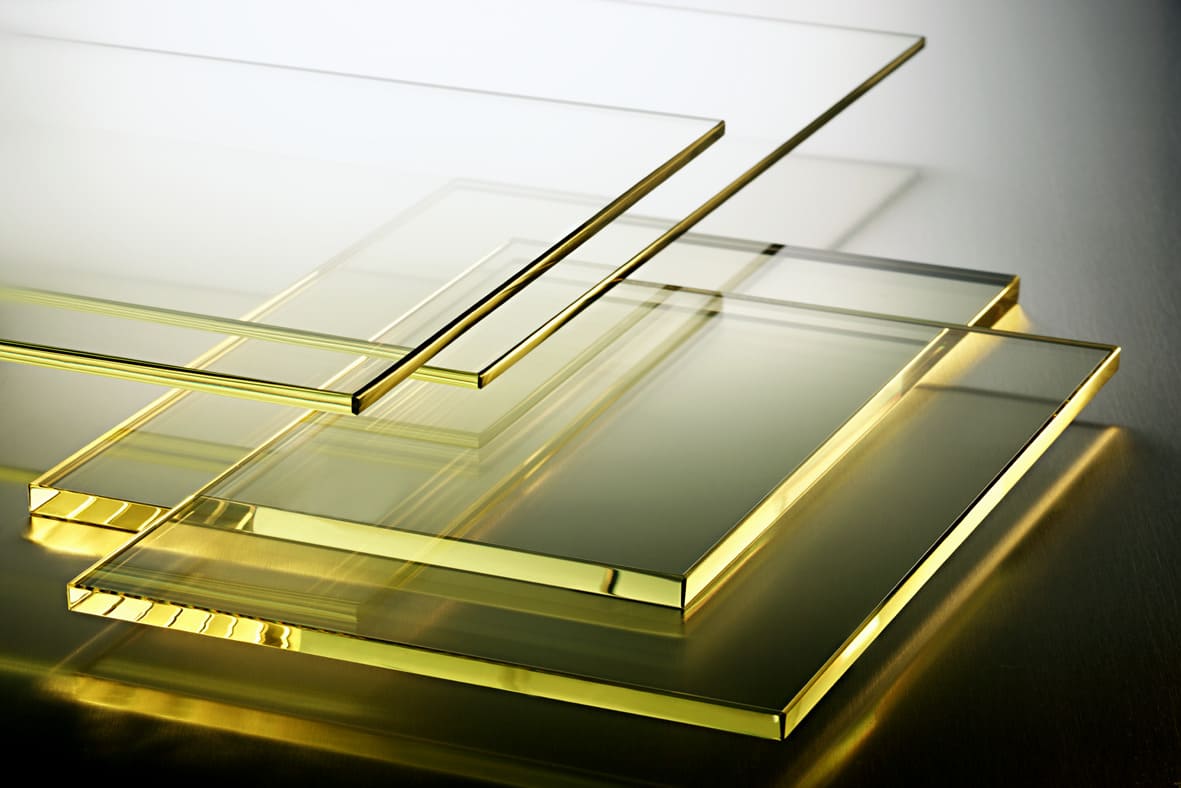

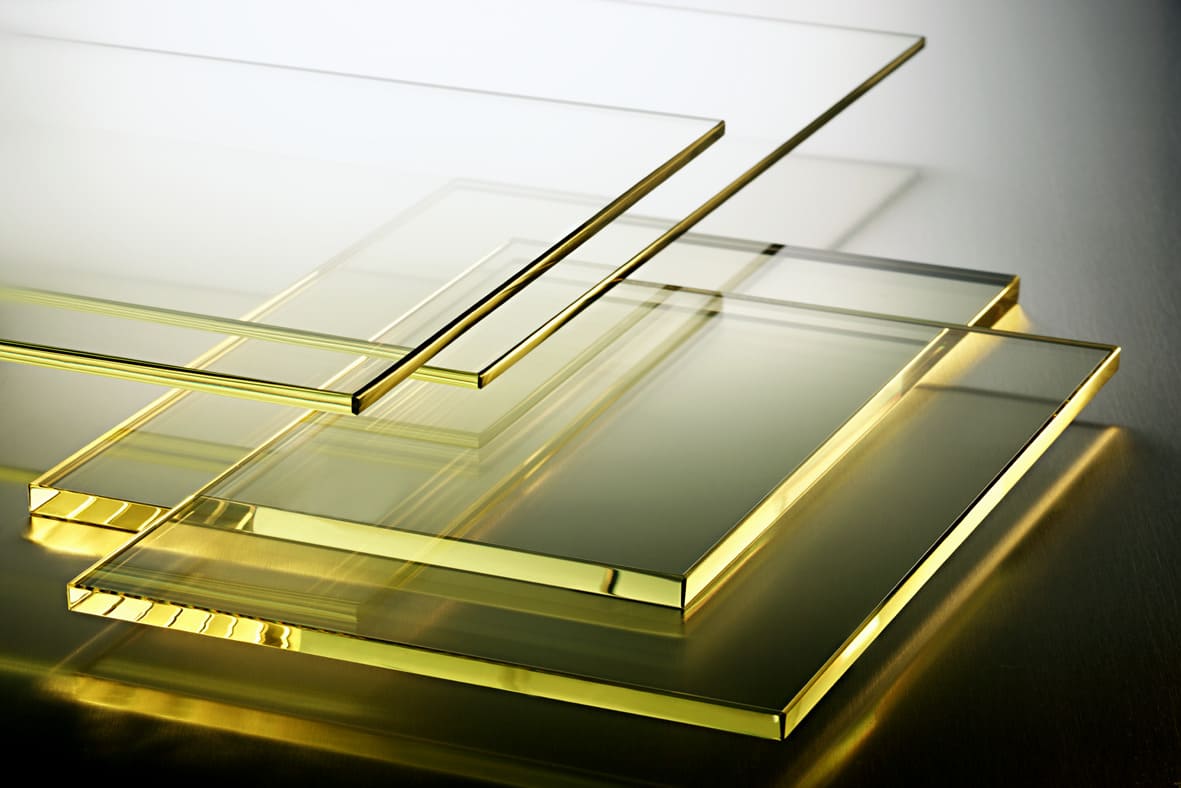

Lead glass is a great example of a sustainable product. And that is just as well, because it is quite expensive. Fortunately, in most situations, when it is included in lead doors or lead screens, for example, it does not suffer that much. It provides years of protection.

Yet lead glass is fragile. Because of its composition, it is very sensitive to acids. These get on your hands, for example. Even cleaning agents or wipes often do more harm than good on lead glass. With the right cleaning instructions for lead glass and, of course, proper attention to this, damage caused by acids can be well prevented. But if, over time, attention to this does slacken, it leads to cloudy lead glass. Cloudy lead glass leaves a haze on the glass that cannot be polished away. This also occurred at LUMC.

In working with LUMC, we give meaningful substance to both LUMC's sustainability policy and our environmental-saving ambitions in a practical way. This can be done by preventing or solving clouding of lead glass. But also, for example, by reusing existing lead glass in new situations or storing lead glass for reuse at a later date. How we do that?

At LUMC, it is common practice to double layer the lead glass with ordinary glass or apply protective film to it for protection. Some older lead panes at LUMC, where no precautions were taken, did eventually become cloudy. Fortunately, the solution to this is simple. Working with a specialised company, we have the lead glass polished. During polishing, radiation safety is maintained. After this treatment, the lead glass is completely clear again and can be used optimally.

In renovations, we dismantle existing lead glass so that it can be reused in a new situation. The size can almost always be adjusted to fit the new window frames. Naturally, the lead value cannot be adjusted.

When it is still not possible to reuse previously used lead glass, for example because the size is too small for the new situation or the lead equivalent is not satisfactory, the glass can simply be stored. If this is done neatly and dry, the glass cannot be damaged or deteriorate in quality. So basically, it keeps its value even when not used immediately.

Want to know more about the sustainable use of lead glass in your organisation? Get in touch!

Enter your details and receive blogs and news items by e-mail.

INTOS uses your data exclusively for sending the INTOS Update.

You will receive blogs and news items by e-mail from now on.